Pharmaceutical standards and requirements evolve and get complex by the time, companies must make sure their employees receive essential education and training to stay ahead of the curve. Training courses includes three main section of general, technical and regulatory concepts training.

Training

Training Powers Your Career

We believe that acquiring knowledge is the essential step to achieve a target and without this knowledge there is no improvement. According to this goal, availability to have the source of concepts and principles in pharmaceutical industry results in improvement and boosting the quality of drug products directly and indirectly and finally human health conditions will raise. In order to enrich available resources for the people in pharmaceutical major, our team in Treata Padideh Sanat co. provides training contents based on guidelines and requirements of FDA, WHO, PIC/S, etc. With this view, we start to present the very first and role concepts. we will provide categorized topics from fundamental and basic concepts to advanced levels by the end of the next year.

Why US?

We offer over 20+ courses spanning the topics of interest to the Pharmaceutical Companies. All these courses based on the last and updated version of EU and FDA guidelines and regulatories.

The major goal of our lecturer are to boost attendees knowledge in order to enhance and improve the culture of manufacturing and product quality.

Available Courses

Companies that take these courses

Student Satisfaction

Courses

You can see all available courses that we offer below, for more information just click on your desired course to see their description and outlines.

Computerized System Validation Course

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

- Authorized persons and Managers

- QA Managers and Experts

- IT Managers and Experts

- Heads of Production and QC

Credit

Certification

- Computer system validation provides documented proof that the system (e.g. Hardware, software, peripherals and network) will repeatedly and reliably do what it is designed to do, is “fit-for-purpose”, and complies with the applicable rules and regulations.

- Validation of computerized systems according to GxP Guidelines (CSV) has been a basic requirement in the healthcare industry for many years.

- Computer system validation is definitely not a “one size fits all” procedure; the approach that an individual company may take to a specific validation depends on the rules, guidance, best practices, and characteristics of the system being validated.

- acquaintance with GAMP5 and CSV Requirements

- Get to know regulatories approach on CSV

- acquaintance with URS and how to write it

- acquaintance with 5 category

- Get to know all the tools and requirments to control and monitor CSV in company

- Understanding all aspects of CSV in order to implement or improve a system

- life cycle approach within a QMS

- Specification and Verification

- Categories of Software

- Five Key Concepts

- 21 CFR Part11

- GAMP5

- Authorized persons and Managers

- QA Managers and Experts

- IT Managers and Experts

- Heads of Production and QC

Good Manufacturing Practice

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

- all personnel who works in pharmaceutical companies

Credit

Certification

- This course will cover one of the most important and essential topics in pharmaceutical Industry which is GMP.

- GMP is one the necessary and basic requirements in pharmaceutical companies and should be obtained and implemented by all employees whom have an impact on the quality of product, there for one of our important courses is teaching good manufacturing practice.

- This course is based on updated regulatories requirement and will cover all 9 titles of GMP and their details. Additionally, in this course, we will discuss different regulatories views and approaches on this subject.

- Depends on audiences’ level, this course can be customized in order to have the best efficacy.

- Acquaintance with all requirements and principals

- Get to know all the regulators view and Guidelines

- Overall understanding of all requirements in each unite such as QC, production and QA

- Acquaintance with all tools and requirements in order to monitor GMP Culture

- Get to know all relevant aspect to implement, improve or work in GMP environments.

- What are cGMPs

- Why are cGMPs so important?

- GMP vs cGMP

- Historical overview of GMP

- Quality Culture

- GMP Scope and responsibility

- GMP Guidance’s

- How to comply with GMP (PIC/S-PE 009-14 (Part I)

- all personnel who works in pharmaceutical companies

Deviation Handling

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

Validation, Quality, IT, and Business personnel

Credit

Certification

Deviations and incidents happening in each company is inevitable but in pharmaceuticals companies should be a strong management, tracking and observation to identify all deviation and do an action to prevent their occurrence.

because of this impotency, knowing and having a sufficient knowledge about deviation and how to implement and manage it when it happens is one the key parameter to achieve a quality.

This course is based on Guidelines and covers all aspects of deviation from the very first step to the CAPA and corrective action.

- acquaintance with Deviation Handling Requirements

- Discuss all relevant aspects to implement, improve or work with Deviation Management

- Get to know the tools and needs to monitor and handle your Deviation and Incidents

- acquaintance with Deviation principle

- Definitions

- Legal Basis for Deviation Management

- Deviation Classification

- Management of Deviation

- Deviation Identification AND Correction

- Root Cause

- Corrective Action, Preventive Action (CAPA)

- Authorized persons and Managers

- QA Managers and Experts

- Production Managers and Experts

- QC Managers and Experts

- all Personnel who work in Pharmaceuticals companies

Pharma Change Control

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

Validation, Quality, IT, and Business personnel

Credit

Certification

Change is inevitable in a pharmaceutical manufacturing operation. Vendors change processes, sources, and specifications for raw materials, equipment requires repair, service, or replacement, manufacturing locations are changed, batch sizes are increased or decreased and advancements in technology are made that dictate changes to the operations. After issuing of Marketing Authorization and/or manufacturing, many changes occurs across the Product lifecycle, i.e. Scaling up of pilot batch into commercial batch and variation in manufacturing processes, excipients and manufacturing sites. All these changes are considered as post approval changes or variations. These variations need to be approved by the respective regulatory authorities of a country. If not, it puts the marketing authorization holder and/or license holder at risk.

- acquaintance with Change Control Requirements

- acquaintance with Infrastructures

- Gaining the ability to Implement this course in company’s system

- Why change control is important?

- Legal basis of Change Control

- Principles of change control

- Change Definitions

- Change Types

- Change Management System-ICH Q10

- Source of Changes

- Regulatory Expectations for Change Control

- Change Control Procedure

- Common Problems

- Changes with respect to CMOs and Suppliers

- Authorized persons and Managers

- QA Managers and Experts

- Production Managers and Experts

- QC Managers and Experts

- all Personnel who work in Pharmaceuticals companies

Self-inspection

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

Validation, Quality, IT, and Business personnel

Credit

Certification

Self-inspection is a method to evaluate one’s own processes and work and find out all faults and correct them before an authorization check them. and is one of the important keys that impact the quality of the product and system.

Self-inspection is an requirement from Regulatory and each pharmaceutical company must do it. all auditors must know how to behave and what to know while they are auditing, they should have knowledge about GMP or theirs companies standards.

This course is based on WHO, FDA and PIC/S guidelines and will cover all of the parameter that one needs to be an auditor and do the inspection.

- Understating self-inspection Requirements, Principals.

- Understanding the relevant aspects to implement, improve or do self-inspection in your companies system

- Get to know all the tools and requirements to monitor and manage the yearly self inception program

- How to behave while Auditing

- What to check while Auditing

- How to prepare for Auditing

- How to prepare a efficient chechlist

- Principles

- Items for self-inspection

- Self-inspection team

- Frequency of self-inspection

- Self-inspection program

- Self-inspection report

- Follow-up action

- Quality audit

- Suppliers’ audits and approval

- Authorized persons and Managers

- QA Managers and Experts

- Production Managers and Experts

- QC Managers and Experts

- all Personnel who work in Pharmaceuticals companies

Cleanroom Behavior

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

Validation, Quality, IT, and Business personnel

Credit

Certification

Cleanrooms are the most important places and should be cleaned/sterilized to be used and they have straight impact on the quality, safety and efficacy of product.

one error and contamination can put the product and health of the thousands of people in risk. so understating this importance and the risk of contamination are the first step in this training course. there are thousands of ways to produce contamination and one whom work or go to cleanrooms areas should be aware of them and know how to avoid from producing or transforming,

Because of this importance all regulators require efficient training for the personnel whom work in this area.

in this course, your personnel will understand everything and practice the requirements that are necessary in cleanroom.

- Understanding Cleanroom Requirements, principals.

- Understanding different grades of cleanroom, acceptance criteria in each grade and the structure of Cleanroom.

- Understanding all source of contamination and to deal with, avoid or control it.

- How to monitor cleanroom.

- What action are allowed and what are not allowed to be done in the clean areas

- Understanding the relevant aspects to implement, improve or behave in the cleanroom.

- Get to know all the tools and requirements to monitor and control the cleanroom.

- Introduction and definitions

- Cleanroom Structures

- Cleanroom Classification

- Contamination Sources

- Contamination Controls

- Cleanroom Monitoring

- Dos, Don’ts

- Authorized persons and Managers

- QA Managers and Experts

- Production Managers and Experts

- QC Managers and Experts

- all Personnel who work in Pharmaceuticals companies

Steam Sterilization

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

Validation, Quality, IT, and Business personnel

Credit

Certification

Successful steam sterilization provides one final outcome; a medical device that is safe for patient contact. This study guide will review Steam Sterilization and help you to understand the theory of steam sterilization, types of steam sterilization cycles and recommended monitoring, components and operation of the sterilizer, and causes leading to sterilization failures.

The fisrt concern of all Pharmaceuticals companies is the patients safety which will be obtained by high quality of the products. So using a devices that are strill and clean that are safe for patient contact is significant.

This Course will review definition of steam sterilization, understanding the importance of it, how to operate and implement, defining types and monitoring and how to avoid from failure.

- acquaintance with Steam Sterilization Requirements, principals.

- Undrestanding the strerilization symbols and methods.

- Undrestan

- Gaining the ability to Implement this course in company’s system

- Introduction

- Sterile Definition

- Sterilization Symbols

- Sterilization Methods

- Steam Sterilization Process

- Sterilization Process Controls

- Sterilization Cycle Design

- Sterilization Process Validation

- Routine Process Controls

- GMP Auditor Considerations

- Regulatory references for moist heat sterilization

- Authorized persons and Managers

- QA Managers and Experts

- Production Managers and Experts

- QC Managers and Experts

- all Personnel who work in Pharmaceuticals companies

CTD Preparation

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

Validation, Quality, IT, and Business personnel

Credit

Certification

This course will provide a clear understanding of CTD and will cover Modules 1-3 contents and what to write, how to write and will discuss about each module and appendices.

- acquaintance with CTD Preparation Requirements

- acquaintance with Infrastructures

- Gaining the ability to Implement this course in company’s system

- Introduction

- Content Of CTD Modules (1-3)

- Relevant Guidance documents

- Discussion Of The Content Module 1

- Module 3, Quality; Drug Substance

- Module 3, Quality; Drug Product

- Discussion Of The Content Module 2

- Discussion On Appendices

- Authorized persons and Managers

- QA Managers and Experts

- Production Managers and Experts

- QC Managers and Experts

- all Personnel who work in Pharmaceuticals companies

Equipment Qualification

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

- QA managers and experts

- Technical Engineering managers and experts

Credit

Certification

- All the equipment that are used in pharmaceutical system should be calibrated and qualified in order to ensure the correct function of them. Because these equipment have the straight impact on the quality of the product and health of mankind. There for, Qualification and implementation of OQ, IQ and PQ tests are so important.

- This course will discuss all principals and definition of qualification, preparing URS and implementation of IQ, OQ and PQ test and will cover all aspects of this subject.

- Acquaintance with qualification principals and requirements

- Acquittance with validation and qualification

- Get to know how to write and prepare URS

- Understanding IQ, OQ and PQ test and their implementation

- Understanding how to provide the qualification report

- Acquaintance with basic step of equipment CSV

- Validation life cycle (V-model)

- VMP

- Qualification plan

- URS preparation

- Functional specification (FS)

- Detailed design

- Design qualification (DQ)

- FAT vs. SAT

- Installation qualification (IQ)

- Operational qualification (OQ)

- Performance qualification (PQ)

- Qualification report

- AIQ

- CSV of equipment and instruments

- QA managers and experts

- Technical Engineering managers and experts

Qualification and Validation

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

- QA managers and experts

- QC managers and experts

Credit

Certification

- In order to ensure that your system, human resources, equipment and processes are work correctly, you need to qualified or validated them. This topic is such an important that you are no allowed to use them before finishing the qualification and validation actions.

- First of all, this course will discuss the difference between validation and qualification, their uses and will cover all aspects of this subject.

- Acquaintance with validation and qualification principals and requirements

- Get to know validation Grades

- Understanding calibration

- Get to know the difference between validation and qualification

- Acquaintance with equipment, premises, environment, process that needs to be validated/qualified

- Acquaintance with process validation

- Understanding cleaning validation

- Validation requirements at the QMS

- Validation Level

- Calibration

- Qualification

- Validation

- Qualification activities

- Equipment

- Analytical Instrument Qualification

- Manufacturing

- Utilities

- Facilities

- Personnel

- V-model

- Validation activities

- Systems

- water system

- HVAC

- CSV

- Process validation

- Cleaning Validation

- Equipment

- QA managers and experts

- QC managers and experts

Analytical Method Validation

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

- Authorized person

- QA managers and experts

- QC managers and experts

Credit

Certification

- AMV plays a significant role to ensure accuracy of analytic data’s and is one the requirements for pharmaceutical companies and should be implemented.

- This course will identify analytical methods and how to select them. Additionally, will cover all aspects of this subject and clarify the standard and non-standard methods

- Acquaintance with AMV principals and definitions

- Get to know all tools and requirements to implement or improve in system

- Understanding all relevant aspects to monitor and control AMV

- Acquaintance with methods and their implementation

- Acquaintance with standard and non-standard methods

- Get to know principals and steps

- AMV Method Selection

- Standard and non-standard methods

- Analytical method modification

- Required statistics for AMV

- Validation performance characteristics

- Specificity

- Accuracy

- Precision

- Linearity

- LOD and LOQ

- Robustness

- Sample Stability

- Authorized person

- QA managers and experts

- QC managers and experts

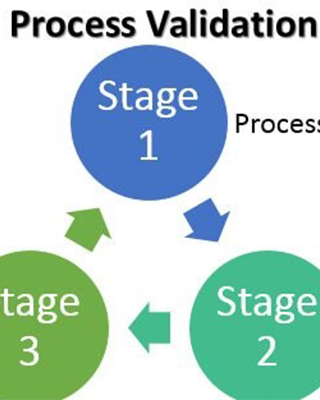

Process Validation

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

- QA Managers and Experts

- QC Managers and Experts

Credit

Certification

A process is the controlled interaction of components, equipment, environment, software and personnel to produce a product or achieve an acceptable outcome. The process validation protocol describes a plan that demonstrates consistency and reliability in processing and confirms that all component, processing and product specifications are appropriate and attainable under ideal and challenged conditions. Successful process validation requires thorough process development, identification of controlled and critical parameters and in-process and final product specifications. Typically at a minimum three (3) consecutive lots of product meeting the established quality specifications are necessary for process validation.

- acquaintance with Process Validation Requirements and principals

- Understanding Process validation and how to perform it

- acquaintance with process stages and their implementation

- Get to know all the tools and requirements to implement and manage process validation in your system

- Definition

- PV vs QA

- Types of process validation trough time of performing

- Prospective Validation

- Concurrent Validation

- Retrospective Validation

- Types of process validation according to process design approach

- Tradition approach

- Enhanced approach

- Enhanced process validation

- Definitions

- Process design (stage 1)

- Process qualification (stage 2)

- Continued process verification (stage 3)

- QA Managers and Experts

- QC Managers and Experts

GQCLP

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

- All QC personnel

- Authorized person

- QA managers and experts

Credit

Certification

- Laboratories same as manufacturing unit provide services although their services may be different such testing, test results, recommendation and investigation.

- There for their services have a straight impact on the quality of the product and they should obtain the requirements from regulatory.

- This course will give you an overall view on all the requirements and principals in good quality control laboratory practice.

- Acquaintance with GQCLP principals and requirements

- Get to know quality management system

- Understanding the tools and requirements to implement or improve GQCLP in the system

- Get to know all relevant aspect to monitor and manage GQCLP environments

- Acquaintance with QC’s SOP and Records

- Get to know equipment, personnel, behavior in laboratories, substance, test methods and data evaluation.

- Organization and management

- Quality management systems

- Control of documentation and records

- Data processing equipment

- Personnel

- Premises, equipment, instruments and other devices

- Materials, equipment, instruments

- Testing procedures and data sheet

- Testing and result evaluation

- Certificate of analysis

- All QC personnel

- Authorized person

- QA managers and experts

Good Documentation Practices

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

- Authorized person

- QA manager and experts

- Production managers and experts

- QC managers and expert

- Technical engineering managers and experts

- All pharma personnel

Credit

Certification

- In pharmaceutical industry, action that is not record is like an action that never done.

- There for one of the fundamentals in pharma companies is documentation.

- Documentations has such an important role that in guidelines there is a one exclusive topic about it and will cover all parameters and aspect of this subjects.

- Although in GMP course, we discuss about GDocP, but in this we will clarify it in more detail.

- Hence, at first level we recommend this course to all pharma personnel, and highly recommend advanced level of this course to all QA personnel.

- Acquittance with documentation requirements and principals

- Get to know the preparation of SOPs and types

- Understanding warning letters

- Get to know all the tools and requirements to implements and improve documentation in system

- Understanding the all relevant aspects to monitor and control the documentation process

- Documents importance (regulatory requirements)

- Warning letters review

- Documentation requirements

- good documentation practices

- Required type of documents

- SOP/STP Writing

- Master formula/batch record preparation

- Specifications

- Authorized person

- QA manager and experts

- Production managers and experts

- QC managers and expert

- Technical engineering managers and experts

- All pharma personnel

Stability Study

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

- QC managers and experts

Credit

Certification

- In order to ensure that the quality of the product is stable in its shelf life, one has to do a stability test. Stability test are two types: real time conditions and Accelerated condition. There for, QA managers and experts should know their differences, methods, implementations.

- We provide a course which not only cover the first and fundamental parameter in this subject but also discuss the climate change and its effect and all types of methods and test.

- Acquittance with stability study requirements and principals

- Get to know Guidelines and references

- Understanding climate change, regions and their effect

- Acquaintance with Photo stability test

- Get to know on going stability test

- Understanding the tools and requirements to control and monitor stability test

- Get to know all the relevant aspects to implement and improve stability test in the system

- Introduction

- Factors affecting Drug Stability

- Stability Guidelines

- Terminology

- Climate zone conditions

- Drug substance

Stress testing

Selection of Batches and Container Closure System

Specification

Testing Frequency

Storage Conditions

Stability Commitment

Evaluation

Statements/Labeling

Ongoing Stability Study

- Drug Product

Photo stability Testing

Selection of Batches and Container Closure System

Specification

Testing Frequency

Storage Conditions

Stability Commitment

Evaluation

Statements/Labeling

- Ongoing Stability Study

- In-use and hold time stability

- QC managers and experts

HSE

Duration

8 hours

Language

Persian/English

Difficulty

Depends on Audiences

Audience

- QA manager and experts

- HSE managers and experts

Credit

Certification

- HSE is a system that is responsible to protect the environment, health and safety of human. So it becomes one of the first and essential subject and unit in industries and will include the pharmaceutical companies too.

- Although this subject is vast and vary but in this we will cover the general definition.

- Acquaintance with HSE principals and requirements

- Get to know how to extinguish fire

- Understanding risks and risk assessments

- Acquaintance with managing change

- Get to know laboratories ergonomics

- Get to know all the tools and equipment to manage and monitor HSE’s system

- Understanding all the relevant aspects to implement or improve the HSE in your system

- Health, Safety and environment Definition

- Fire Safety

- Cylinder under pressure safety

- Identifying Hazard and Risk Assessment

- Cost of incidents

- Change management

- Laboratory Ergonomics

- Chemicals Health, Safety and environment management

- امواج یون ساز و غیر یونساز

- GHS Standards

- Chemicals labeling

- MSDS Structure

- Chemical risk assessment

- Control hierarchy

- QA manager and experts

- HSE managers and experts